Software for managing and automating business processes in quality and production

NexOne is our software developed for the management andautomation of business processes in quality and production. It is characterised by its ability to integrate, analyse and manage data from a wide range of sources in real time.

It was entirely designed and built by the Nexeeva programming team and can be used within all industrial sectors: automotive, mechanical engineering, hydraulics, medical, textile, food, etc.

How does NexOne work?

Acquisition

Registration and archiving

Management and analysis

Acquisition

Acquisition

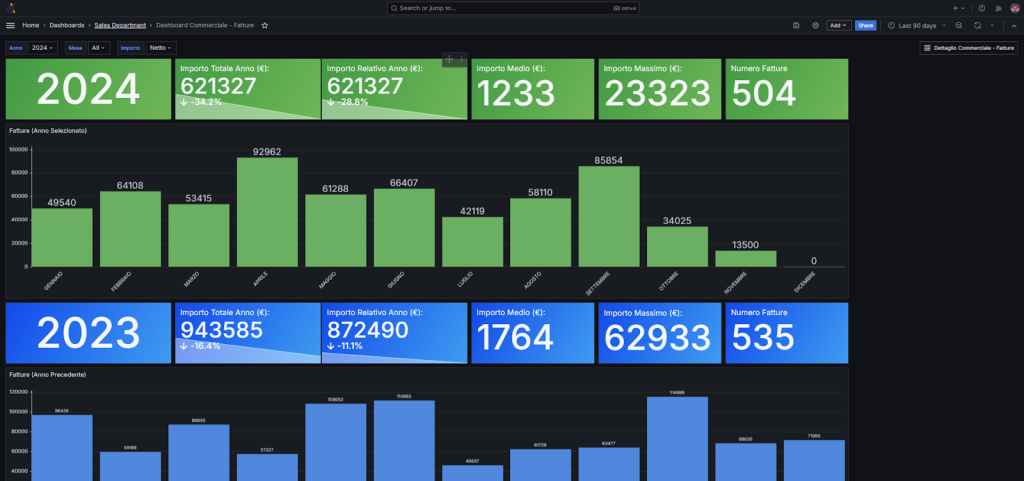

By means of interactive dashboards , NexOne acquires and records real-time data related to the production lines and coming from different applications, and then represents it graphically and makes it available for consultation.

This data is a key resource as it enables an immediate understanding of the information, leading to faster analysis and more informed decisions. In this way, the company can identify any slowdowns, downtimes or bottlenecks in the production process and activate corrections and changes, thus improving the efficiency of production lines.

With the data collected, the company is able to calculate its OEE, Overall Equipment Effectiveness: this is the performance index (KPI) that measures its production capacity, machine and operator efficiency.

NexOne is compatible with Windows and Linux systems and can interface with any type of machine, including analogue.

The NexOne software uses the following technologies:

- ETL system with Pentaho for collecting, transforming and loading data from various heterogeneous sources such as production, purchasing and quality control. Pentaho makes it possible to access data that would otherwise be inaccessible and use it for the company’s business.

- Grafana Dashboard as an intuitive and customisable interface to display data in one accessible place in a clear and effective manner. The dashboard interface is interactive, with charts, tables and maps accessible from any device.

2. Registration and archiving

2. Registration and archiving

Data (including files and images) are collected and stored in a centralised repository or in the cloud, which is indexed by production line.

The production flow is dynamic, secure and free of any downtime due to connectivity problems as the repository is built with its own internal database and independent of the connection to the central data repository.

It is also possible to configure dedicated local storage for each production line.

Management and analysis

Management and analysis

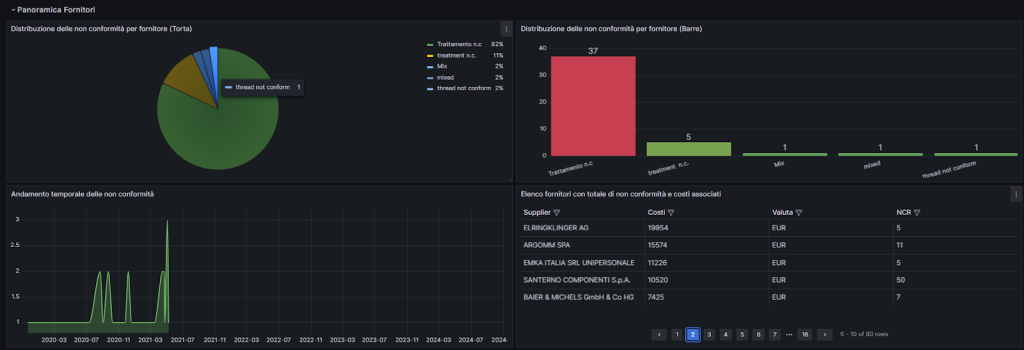

NexOne organises the data from the various production lines and machines within dashboards; the summary dashboard analysis provides a complete overview of the production processes and their performance.

The data can then be consulted by means of special filters, to view the history of production lines, machinery or parts produced/discarded.

NexOne can be connected to ERP (Enterprise Resource Planning) and business management systems, industrial automation equipment PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) and all other systems to centralise data, avoiding duplication.

It therefore retrieves information useful for the activity to be managed without having to enter and maintain this information on several systems: article master data, customer/supplier master data, receipt orders, production orders, operators and company personnel, price and cost lists.

It allows any type of document to be attached and allows batch information to be tracked, cross-referencing the data collected during the sampling/incoming/production phase with information also present in ERPs or other company management systems, in order to have unambiguous data.

Several modules, one tool

NexOne has several modules that are integrated and easy to manage. With one configuration, in essence, and one tool, it is possible to fulfil several functions.

All NexOne Quality Modules

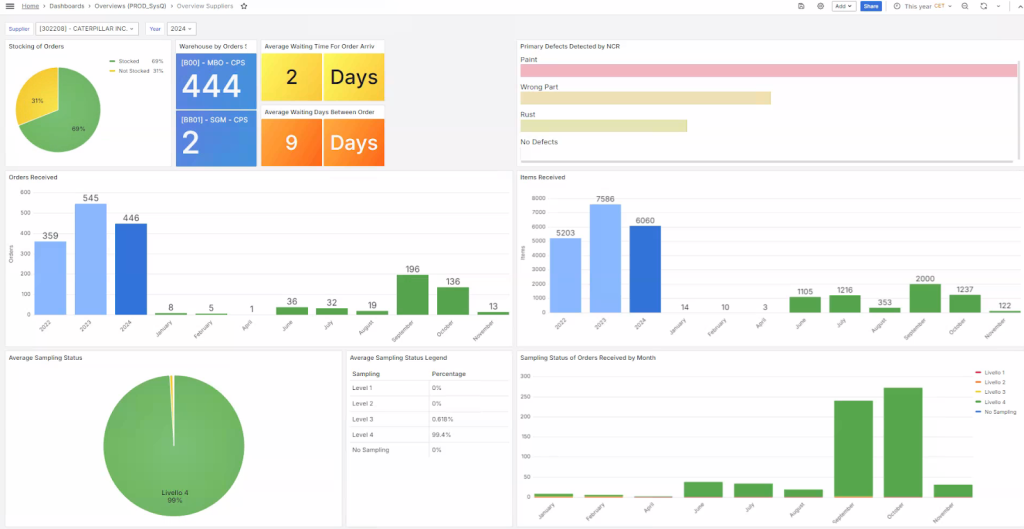

Receipt module – goods receipt control

The operator can record all information concerning the receipt of goods and related operations. It is divided into two sections: orders to be inspected and inspected orders.

Orders are retrieved directly from the ERP (or company management system) via an automated procedure. For each order, NexOne creates a dedicated sheet containing all data relating to the technical characteristics to be sampled. The sheet can be customised.

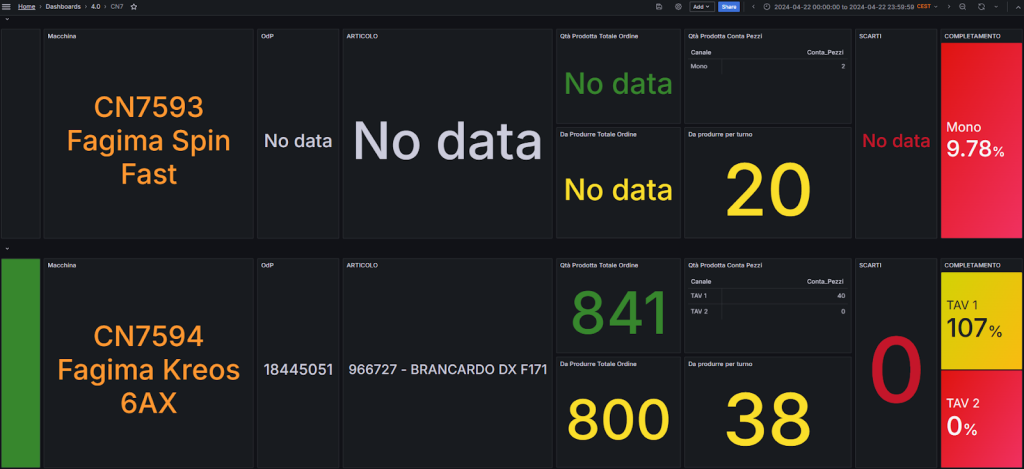

Production module – production control

It records all production data, which is then broken down by company and warehouse according to production lines.

Each production line is assigned a card that allows it to be identified:

- the article to be produced and the batch to which it belongs;

- quantities produced and waste;

- downtimes and their causes

The module also provides information on the productivity of personnel in the company: it records the minutes of absence and presence and the number of items produced in relation to each operator.

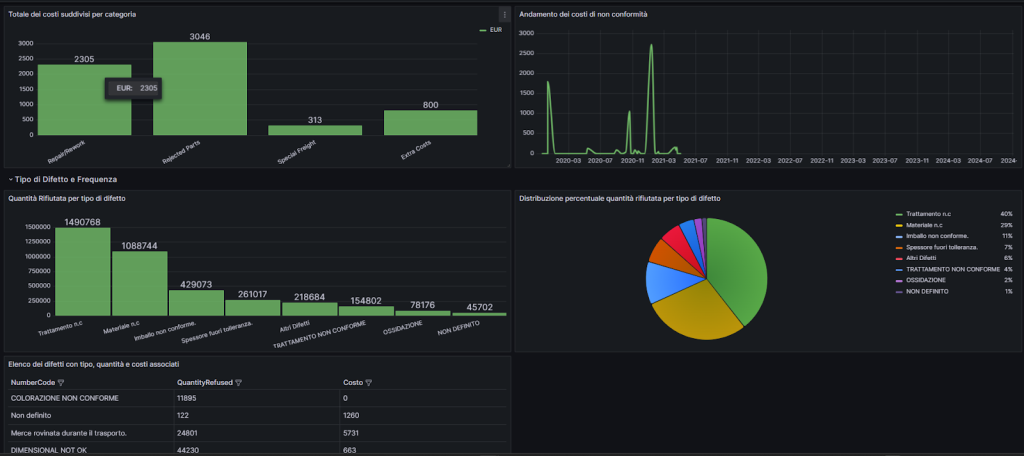

COPQ (Cost of Poor Quality) module cost analysis

The COPQ (Cost Of Pure Quality) module allows the administrative staff to take over the various cost items within an NCR non-conformity report and to create special sheets.

In this way, the quality department in the company is immediately notified of the intake and status of costs:

- been closed.

- suspended state: when a negotiation with the supplier is in progress;

- finance status: the cost is billable;

Non-conformity module

It collects and manages all non-conformity reports (NCRs): once the data on the article in question, such as the quantity received, the quantity rejected and the description of the defects found, is entered, this information is automatically retrieved by the system.

It is then possible to print the document certifying the NCR: the template of the document can be customised and can be attached to the communication intended for the supplier (integrating, if desired, all the contacts to whom a copy should be sent).

Waste management

It collects all documents and information relating to rejects, such as: the company and warehouse where the rejection took place, the date on which it took place, the type of article and description of the defect found, what action was taken after the irregularity was found, etc. The rejection can be added to the production module, thus integrating it with the production sheet in the system.

Data traceability

The module allows full traceability of all information related to the article or batch as it interrogates all documents within the NexOne software: from receipts to inspections during reception and also during production, within rejects and non-conformities.

Thanks to this module, it is possible to carry out searches on the article and batch and to display all movements including the date of receipt and control.

Production Capacity Calculation – XBAR and RCHART Charts

By crating Xbar and Rchart graphs, it monitors the stability of a production process and its variability over time, using data obtained from product sampling.

Workflow:

>> Data Collection: the user selects the article and the period of analysis. The module extracts the sampling data.

>> Calculation of values for graphs: averages and variations are calculated for each sample. The data are represented in Xbar and R Charts.

Xbar Chart shows the trend of the average of the samples over time, to see if the process is stable; R Chart represents the variability within each sample, showing the maximum-minimum range.

>> Detection of deviations: the system reports any anomalies or critical trends.

>> Quality improvement support: allows operators to quickly identify variations in the process and make timely corrections.

Connects to any type of machine

NexOne is compatible with Windows and Linux systems and can interface with any type of machine, including analogue.

NexOne records and acquires the data of each machine while it is in action in the production phase: in this way, it is able to monitor all the process values that determine the goodness of the final product, values that could vary over time due to conditions of use and/or other factors that would make it defective.

Let’s take an example.

Let’s say the machine ‘under analysis’ is a press: any abnormal oil consumption could generate a different or excessive pressure that would make the final product defective. NexOne is also able to intercept and record the piston force, collecting in real time all the information necessary to avoid malfunctions and therefore defects in the product which qualitatively would not meet the required specifications and could therefore be rejected.

Why choose NexOne?

It is secure, user-friendly, interactive and fully customisable software.

It is secure, user-friendly, interactive and fully customisable software.

It integrates plant and machine data very quickly.

It integrates plant and machine data very quickly.

It provides real time reporting.

It provides real time reporting.

Evaluate performance with clear data.

Evaluate performance with clear data.

It identifies weak points in production.

It identifies weak points in production.

It optimises time and improves the quality of the materials received.

It optimises time and improves the quality of the materials received.

It is accessible from any computer or mobile device that can be integrated with software and hardware systems.

It is accessible from any computer or mobile device that can be integrated with software and hardware systems.

It is equipped with an alerting system that sends notifications in case of criticality.

It is equipped with an alerting system that sends notifications in case of criticality.

Why invest in quality and production efficiency?

In the context of Industry 4.0 and digitisation of business processes, quality management and production control through customised software are indispensable because they enable the company to:

- automate data monitoring;

- verify product quality and reduce production defects;

- maintain product conformity with national and international regulations;

- tracking the activities and people involved in the various stages and processes;

- immediately identify the sectors and areas in the company that need to be improved and strengthened.

All this translates into improvement of the company’s organisation and quality, which are necessary conditions for increasing the productivity index of resources, reducing production and maintenance costs and times, increasing plant productivity and having better performing products. Quality and organisation also improve working conditions and create a more favourable environment in the company.

Industry 4.0 capital goods tax credit

The NexOne software is part of the enabling technologies for Industry 4.0 and therefore enjoys the tax benefits provided by the National Transition 4.0 Plan: all companies that make investments in new capital goods intended for production facilities located in the territory of the State are granted a tax credit.

Contact us

By choosing our NexOne software, you can count on our support: serious, reliable and always available.

Contact us for more information on the software and all our services.